iForm: The Most Advanced ICF

iForm is recognized as the most technologically advanced ICF in the industry due to its innovative design and technical features, setting it apart from other ICF products. iForm has become the ICF of choice for commercial projects, including strip malls, multi-story condominiums, hotels, theaters, schools, churches, assisted living and nursing homes, and a wide range of residential projects.

iForm is recognized as the most technologically advanced ICF in the industry due to its innovative design and technical features, setting it apart from other ICF products. iForm has become the ICF of choice for commercial projects, including strip malls, multi-story condominiums, hotels, theaters, schools, churches, assisted living and nursing homes, and a wide range of residential projects.

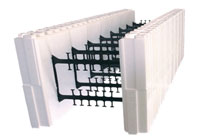

iForm functions as the formwork for a cast-in-place concrete wall, which remains in place as insulation on both the exterior and interior faces of the wall assembly. Additionally, it serves as an attachment point for exterior and interior finish systems. The system creates a solid, flat, steel-reinforced, cast-in-place concrete wall available in thicknesses of 10 cm, 16 cm, 20 cm, 25 cm, or 30cm to serve as the structural component of the wall assembly.

iForm is used in commercial and residential construction for both exterior and interior, load-bearing and non-load-bearing, above-grade and below-grade walls. Applications include frost walls, basement walls, storm shelters, demising walls, slab-on-grade walls, non-load-bearing walls on post-tension floor slabs, and single-story to multi-story walls.

iForm Types

All iForms manufactured by Gwalls are available as modular types. The type and size of the product are determined by structural requirements, fire and sound rating needs, and the preferences of the designer or owner.

iForms come in different types to streamline the construction process: